Silver conductive adhesive paste, also known as conductive paint, is a material which is highly conductive. It looks like glue, but it is conductive and has a gray color. This innovative material is not only used in industry but also for research purposes.

Main usage purpose of this material is to convert insulative surfaces into conductive surfaces. It is denoted by Ag, and it has purity of %75 so it is highly conductive electrically and thermally. As the name of the material implies, the adhesion of this material is high meaning that it can adheres to any surface easily.

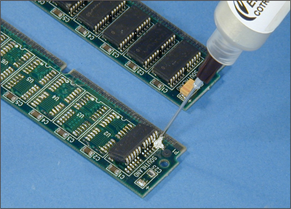

It is the raw material for printable conductive ink which is mostly used in printed circuit boards (PCB). PCB’s are the main part of the computers, smartphones and many other devices so application field of silver conductive adhesive paste is broadened fort the past decades.

One of the main advantages of this material is that it can be easily applied to surfaces that cannot be soldered. It quickly becomes dry after applying to the surface due to its volatile solvent base and becomes ready to use after short time application to the surface. In addition to these, its viscosity can be easily customized since it dissolves in suitable thinners readily. All these properties show that conductive silver adhesive paste is convenient in terms of application.

Figure 1: Application of Silver Conductive Adhesive Paste on a PCB

Advantages of Silver Conductive Adhesive Paste

- It protects the sensitive inner components from the harmful effects of electromagnetic radiation.

- Excellent durability – extremely hard material after curing

- High joint strength

- Room temperature storage

Applications

Silver Conductive Adhesive Paste is used:

- as a conductor on printed circuit boards

- in manufacturing of PV solar cells.

- in electronics industry for the purpose of soldering

- as an alternative material for soldering temperature-sensitive components in electric circuits

- as an inner coating material for storage boxes of electronic devices.

Read More About This Material:

Comments

Post a Comment