Could Graphene Use Create A Distruptive Technology In Tyre Sector?

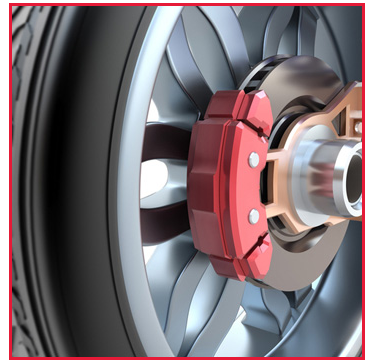

https://www.canadacarbon.com/brake-linings-gasket...

In 2016 GraphChina (Graphene Innovation Conference); Sentury and Huagao launched their first electrostatic conducting graphene tyre on September 22nd. 2-3 weeks before the conference Sentury and Huagao officially announced their cooperation on the product.

During the press conference, Sentury’s engineers (which is branded with the Landsail moniker), revealed that the latest test data shows their graphene-enhanced tyre offers; 1.8 meters shorter stopping distances (6 % improvement on conventional technology), between 1.5 and 1.8 times conventional mileage, 1.5% improvement in rolling resistance as well as a 10% weight decrease. If these improvements are achieved – it seems that graphene began to be a wonder material in the tyre sector as well.

On the first week of August 2016, Sentury Tire and Huagao revealed that the companies produced their first trial production of graphene tyre in October 2015, the 245/45 R18 LS588@RSC electrostatic tyre.

Just one tyre and is that all? Apparently not. Back then, the production plan is 5 million units in the first five years with an output set to increase it to 10 million in the second five years. To quote the companies themselves: “Sentury and Huagao will lead the industrial revolution in graphene-tyre field”. However, Hengyu and Vittoria are also on the scene now (as well as others that have not yet put their heads above the trench), executing this ambitious vision will be quite a challenge.

http://www.xxvii.com/brand/vittoria/vittoria-qura...

The other commercialized example is bicycle tyre manufacturer Vittoria has added graphene to its tyres to improve their puncture resistance. According to company's senior executive manager Michael Marx; graphene makes the tyres lighter, with less rolling resistance and more grip - something which was impossible using existing compounds. The addition of this nanotechnology material results in a faster, stronger, more resilient carbon-composite material. Graphene-enhanced composites have 10-30% improved material properties. Tests carried out by Vittoria’s R&D engineers, confirmed by external laboratories, showed that introducing graphene into the rim’s carbon-fiber matrix has a great positive impact:

If you want to use graphene in tyres applications, the best products are here:

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-3-nm-s-a-300-m2-g-dia-1-5/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-3-nm-s-a-500-m2-g-dia-1-5/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-3-nm-s-a-750-m2-g-dia-1-5/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-6-nm-s-a-120-m2-g-dia-24-m/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-6-nm-s-a-120-m2-g-dia-5-m/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-6-nm-s-a-120-m2-g-dia-16-m/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-6-nm-s-a-150-m2-g-dia-16-m/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-6-nm-s-a-150-m2-g-dia-24-m/

https://nanografi.com/graphene/graphene-nanoplatelet-99-5-6-nm-s-a-150-m2-g-dia-5-m/

https://nanografi.com/blog/graphene-tyres-and-graphene-brake-pads/https://nanografi.com/blog/graphene-tyres-and-graphene-brake-pads/

https://nanografi.com/graphene/single-layer-graphene-oxide-nano-powder-99-

Sentury Touring Tire Review

ReplyDelete