Carbon nanotubes (CNTs) have attracted enormous attention in recent years due to its unique physical, electronic, optical and potential applications in materials science and nanotechnology. The van der Waals interaction between tubes, however, makes CNTs aggregate in most organic solvents and aqueous solutions, which is the major limitation of their practical applications.Various approaches have been studied to alter the CNT surface to promote the dispersion of individual nanotubes and prevent their reaggregation. On the basis of this widely accepted viewpoint, numerous techniques such as covalent bonding, surfactant coating and polymer wrapping have been developed for surface modification or sidewall functionalization.These methods, however, are complicated, time-consuming and cause permanent damage to the CNT structure and properties of the surface, which produces residues of the dispersion agent for the final product.

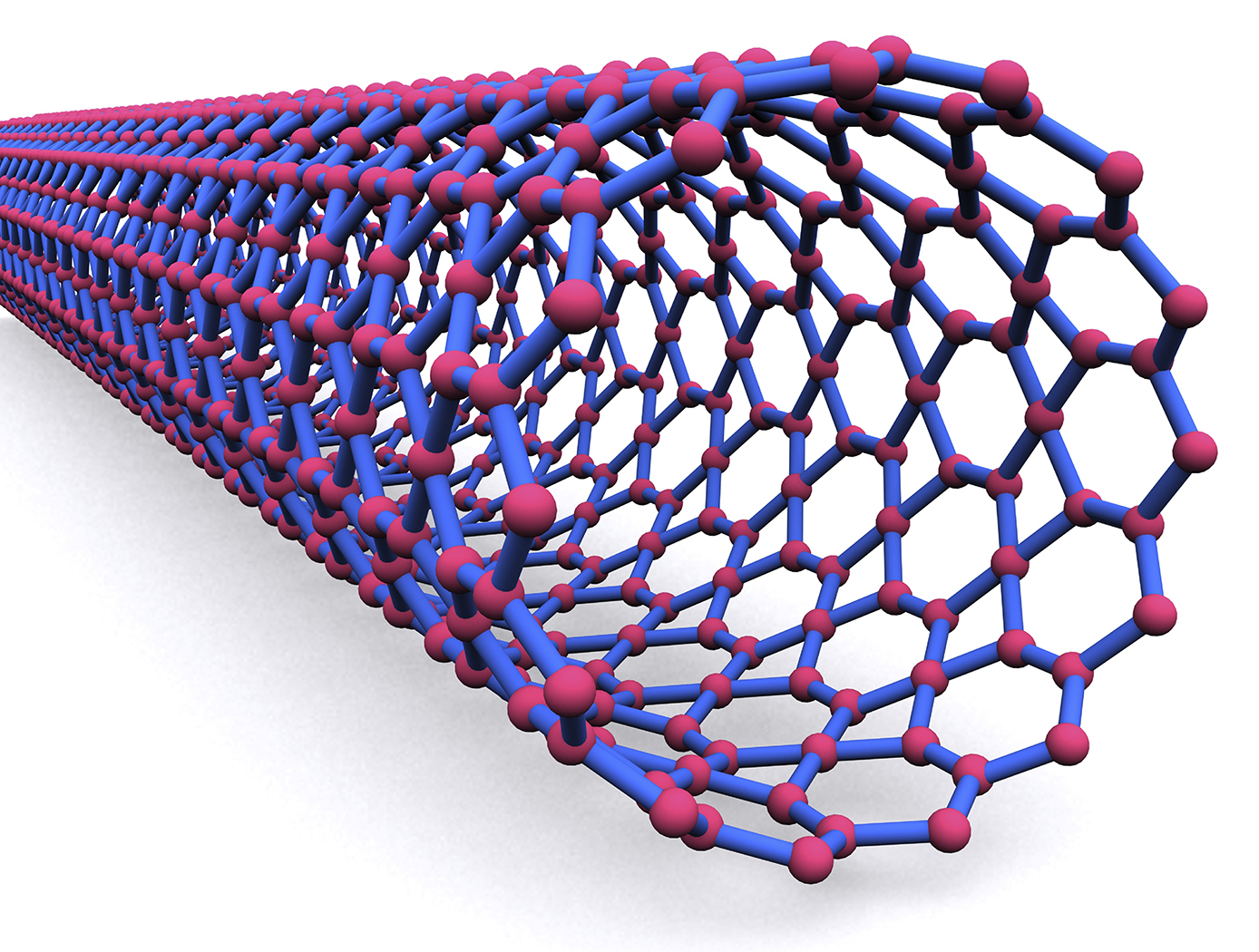

Figure: Single Walled Carbon Nanotube (SWCNT)

It has recently been found that pristine single-walled CNTs without any surface functionalization have been significantly debundled in certain organic solvents and are relatively stable.In addition, pristine SWCNTs without chemical treatment have been used in the preparation of composites of polystyrene and polyurethane after they have been well dispersed into organic solvents.The SWCNTs as well as the MWCNTs have uniqueness and promising features.Compared to SWCNTs, MWCNTs have obvious low-cost advantages and are better suited to industrial marketing.Although there is growing interest in the dispersion in organic solvents of pristine SWCNTs, so far few reports have indicated that common organic solvents have dispersed pristine MWCNTs.

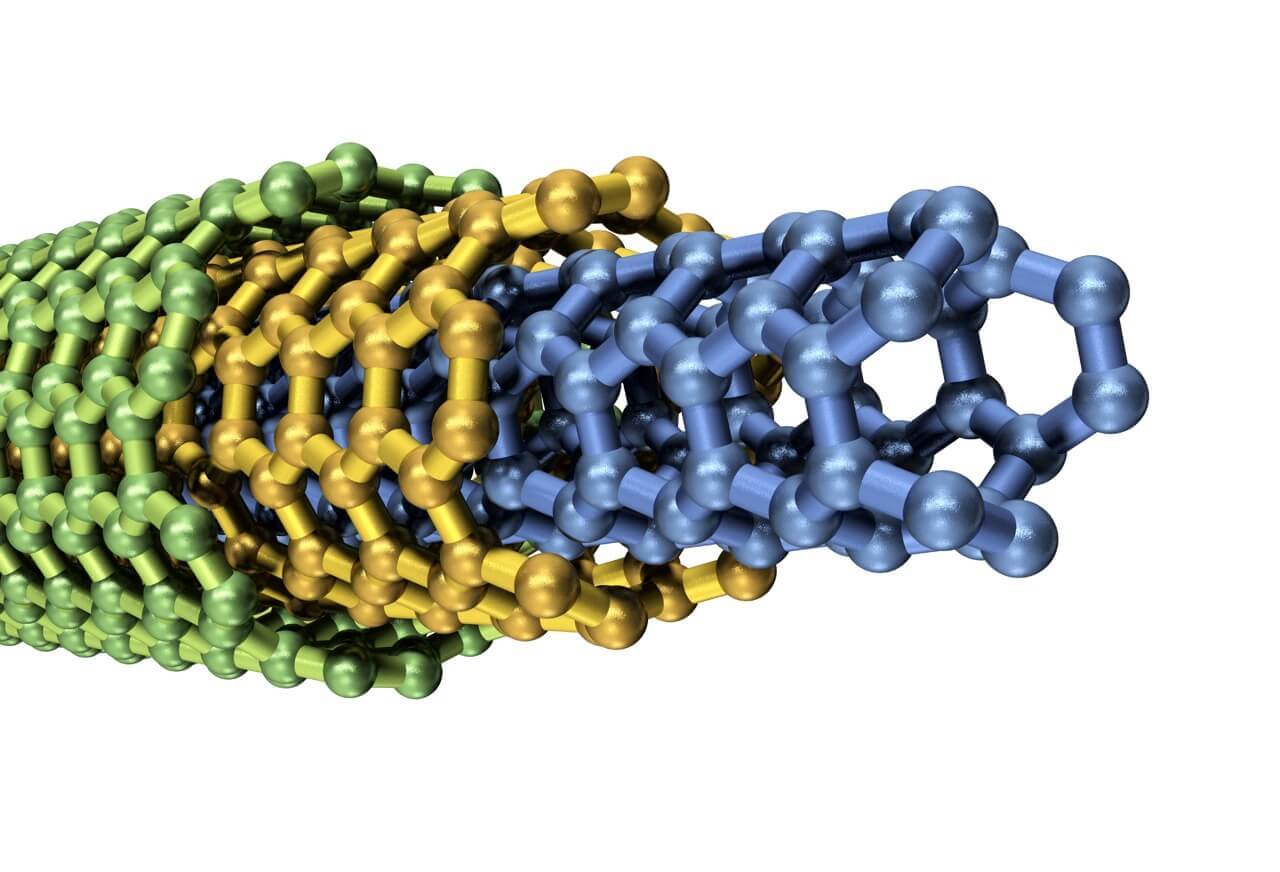

Figure: Multi Walled Carbon Nanotube (MWCNT)

MWCNT consists of several nanotubes of carbon nestled inside each other.There are between 3 and over 20 nanotubes within an MWCNT.At the same time, both the internal nanotube and the external one can vary in diameter from 2 nm to more than 50 nm to the external part of the tube.They have excellent electric, thermal and mechanical properties, just like single walled nanotubes.MWCNT can be manufactured and purged in high quantities (compared with single wall and double wall nanotubes). This significantly reduces their production costs and is why they are adopted in several areas of scientific research.

The applications of MWCNTs focus mainly on their application in composite materials, where they can either improve the mechanical characteristics of a matter or improve the electrical characteristics of a material as an additive.In addition to the use of functional MWCNTs as additives, they are used in a variety of medical and biological applications.This is because they are highly biologically compatible with carbon nanotubes and can attach specific proteins to functional groups.This can provide a range of specific treatments, such as drug delivery, local heating for cell death, or even therapeutic biosensors for in-situ measurements.

Comments

Post a Comment