What is Radiation Shielding?

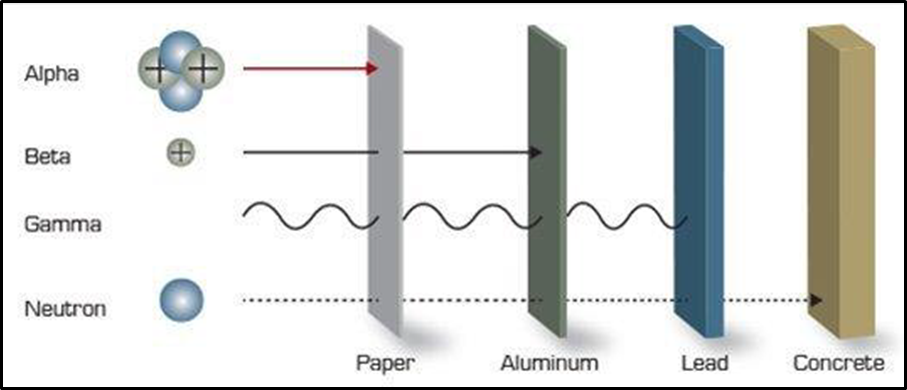

Radiation shielding has been an important subject of scientific investigations for years because radiation affects human’s health at the first place. Scientists try to keep the radiation at minimum level with optimum materials. Almost any material can act as a barrier to gamma or X-rays but the efficiency, size, mass, cost, etc. are the determinant parameters for material selection. Lead, tin, copper and concrete are the most commonly used materials for radiation shielding these days. Figure 1 below shows schematic illustration of some radiation shielding materials.

How is Graphene used for Radiation Shielding?

Graphene (see Figure 2), which is a special form of Carbon, is in a category of weak radiation absorber due to its low atomic number value, Z=6. This is not a surprising fact considering its only one layer of atoms thick. However, recent studies have shown that graphene can be used as radiation shield when it is in multilayered form,graphene slab. A graphene slab is approximately 10 μm thick and contains over a dozen thousands of single layers.

"However, recent studies have shown that graphene can be used as radiation shield when it is in multilayered form, graphene slab."

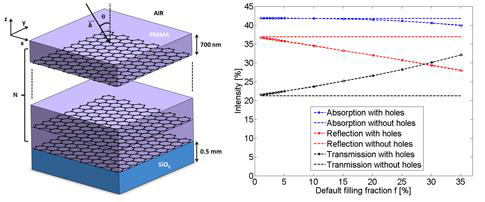

In layered structure, the most efficient absorbing layer must have a conductivity that matches the sum of admittances of the two media located on both sides. In free air, the corresponding conductivity is 5.31 mS square, which corresponds to a resistance of 188 Ohm/sq.

A few graphene layers, parallel to each other, can achieve these values.

An experiment conducted by Universite De Namur has proved this fact. In the experiment thin polymer films each covered with graphene were put layer by layer to determine how many layers is needed to absorb microwave. Only six layers were enough to absorb the microwaves. The same experiment was conducted with metallic layers having thickness of 3-5 nm but it was very fragile against bending and corrosion.

Another study also showed that graphene oxide removes some of the most toxic and radioactive long-lived human-made radionuclides from contaminated water, even from acidic solutions having pH value below 2.0 (Anna, Alexander, Kalmykov & James (2013)).

All in all, radiation shielding is an important technological issue since radiation is a huge concern for both humans and future nanotechnology. As it is discussed in many studies, graphene is new the projected shield material owing to its low manufacturing cost, light weight and high effectiveness of absorption of radiation compared to other conventional shield materials.

Read More about Uses of Graphene on Blografi:

Comments

Post a Comment