Graphene is a two-dimensional nanomaterial which is composed of monolayers of sp2-bounded carbon atoms. Graphene has drawn considerable attention in both academic and industry area for various potential applications including semiconductors, energy storage devices, and sensors due to their physical properties such as high room-temperature mobility, high thermal conductivity.

Obtaining single layer graphene or few-layer graphene by adhesive tape or cleavage methods is not practical because these methods provide only limited opportunity for scaling up the graphene. However, the chemical vapor deposition (CVD) process has been explored to synthesis large size single crystals and uniform films of monolayer graphene and bilayer graphene. CVD is a method to produce graphene which is fast, cheap and scalable. According to the experiences of graphene synthesis, it is well known that the growth of graphene is much easier from what is called ‘seed’.

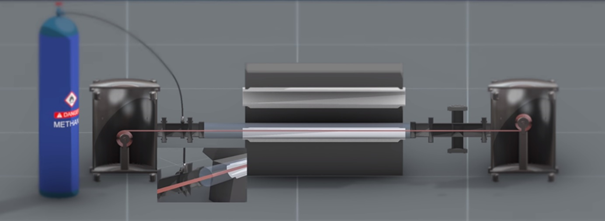

Chemical Vapor Deposition Process

CVD process is basically a method of depositing gaseous reactants onto a substrate. In CVD, pre-conditioned graphene (i.e. carbon nanotube, diamond) is scaled up by bombarding chemicals at high temperatures and pressures. The ‘seed’ (i.e. tiny pieces of actual diamond) is prepared for bombarding of chemicals. Then, high heat and pressure are applied, and chemical vapor deposit which contains carbon atoms (generally methane, CH4) is sprayed onto the seed. After some time (few days), grown graphene structure is obtained.

In CVD process there are several conditions which needs to be taken into consideration. In this prospect, the nucleation and growth mechanism of graphene on a catalytic substrate play the fundamental role in the formation of large domains and number of layers. The transition metals, alloys, and liquid metals have been recognized as the catalyst for growth of monolayer and bilayer graphene, where the surface composition of solid catalyst substrates also plays critical role on graphene growth. The thermodynamic and kinetic parameters are also crucial in graphene growth process, where pressure and temperature are both key factors.

To conclude, CVD is fast, cost-effective way of graphene production. Since by CVD, high quality graphene can be manufactured; it can be used in electronic applications such as creation of transistors and photovoltaic cells. In the future, CVD will be the most preferred method of synthesis of graphene.

Read more about this product:

Comments

Post a Comment