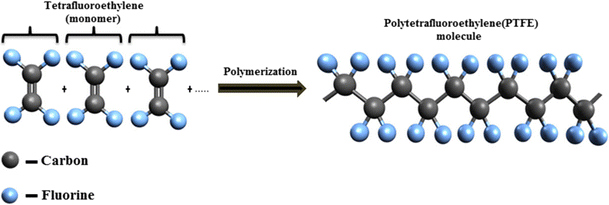

PTFE(Polytetrafluoroethylen) is a white colored thermoplastic which has a high corrosion and heat resistance. Having significantly low friction coefficient makes it an outstanding material in various applications such as seals, O-rings and gasket etc. Also, it is used with other polymers or used as a reinforcing material in composites for special applications. Since it is hydrophobic material, it is also a non-wetting material. PTFE nanopowder has a structure that is made up of only fluorine and carbon atoms shown in the Figure 1. Another important property of PTFE is that can be extruded easily which makes it convenient in shaping operations such as insulation of electric wires and unsintered tapes.

Properties of PTFE Nanopowder

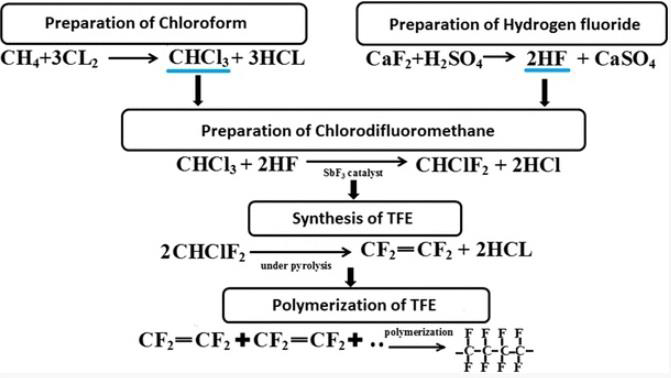

Manufacturing process of PTFE

PTFE is obtained by polymerization of tetrafluoroethylene (TFE) monomer to form PTFE molecule.

Casting Techniques of PTFE

One of the widely used method for casting of PTFE is molding method. Molding method has different types of processes such as compression molding, injection molding, extrusion molding and blow molding. Compression molding is the most common one to cast PTFE.

Another method used for casting of PTFE is blending. Types of blending process are solution blending and melt blending.

Applications of PTFE

Due to its superior properties, PTFE has been used extensively in various industry fields.

Automotive industry: PTFE is mostly used in gear systems of the cars for lubrication purposes because all bearing requires oil or grease. It is used as a self-lubricating ball bearing due to its low surface energy.

Petrochemical and power industries: Due to its tribological property, it is used as a functional material in machining equipment such as gaskets, rings, seals etc.

Chemical industries: PTFE is high-resistant to chemical attacks which makes it preferable in chemical processes. PTFE is used as a coating material for acid containers, tubes, hoses, and valves.

Electrical applications: PTFE is extensively used as an insulating material in electrical devices regardless of the size of the components. Most commonly, it is used as a wire insulator.

Comments

Post a Comment