Rechargeable lithium ion batteries have wide applications in electronics, where customers always demand more capacity and longer lifetime. Lithium ion batteries have also been used in electric and hybrid vehicles or even electrical grid stabilization systems. All these applications simulate a dramatic increase in the research and development of battery materials, including new materials, doping, nanostructuring, coatings or surface modifications and novel binde18. Consequently, an increasing number of physicists, chemists and materials scientists have recently ventured into this area. Coin cells are widely used in research laboratories to test new battery materials; even for the research and development that target large-scale and high-power applications, small coin cells are often used to test the capacities and rate capabilities of new materials in the initial stage.

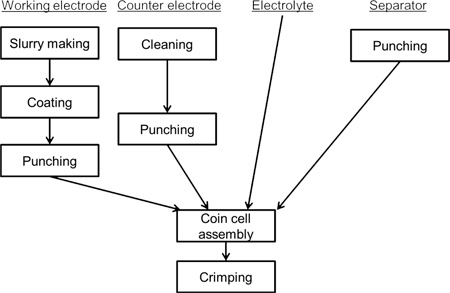

You may see flow chart of the coin cell construction procedure below. First, a working electrode is prepared from the powder of the active material. Then, a counter electrode is prepared from a clean lithium foil and the separators are punched out. Finally, a cell is assembled inside an argon glovebox.

From the chart as you can see, the last operation is crimping. To obtain a high-quality cell crimping process has an important role. For this operation you may use hydraulic crimping machine. You may see the importance of crimping process from the image given below. A badly crimped coin cell splits open after a few hours in ambient due to the swelling of lithium foil after reaction with moisture.

With our hydraulic crimping machine, you may be 100% sure that you will not face with kinds of problems. Our hydraulic crimping machine MSK-110, is a new design and CE Certified coin-cell crimper with lighter weight and a smaller footprint. The crimper is suitable for sealing various types of coin cells such as CR2032, CR2025,and CR2016 with included die. Our hydraulic crimping machine can also crimp CR2325, CR2450, AG3, AG5 and other special size cases with optional die sets. In addition, customers can easily replace the original die for disassembling purpose. MSK-110 is ideally operated in a glove box.

For detailed information about coin cells and their preparation you may clink the link given below.

You can give an order of our hydraulic crimping machine from the link given below:

Comments

Post a Comment