Image retrieved from: http://www.ciaindumentaria.com.ar/plataforma/wp-content/uploads/2014/09/nanopic.jpg

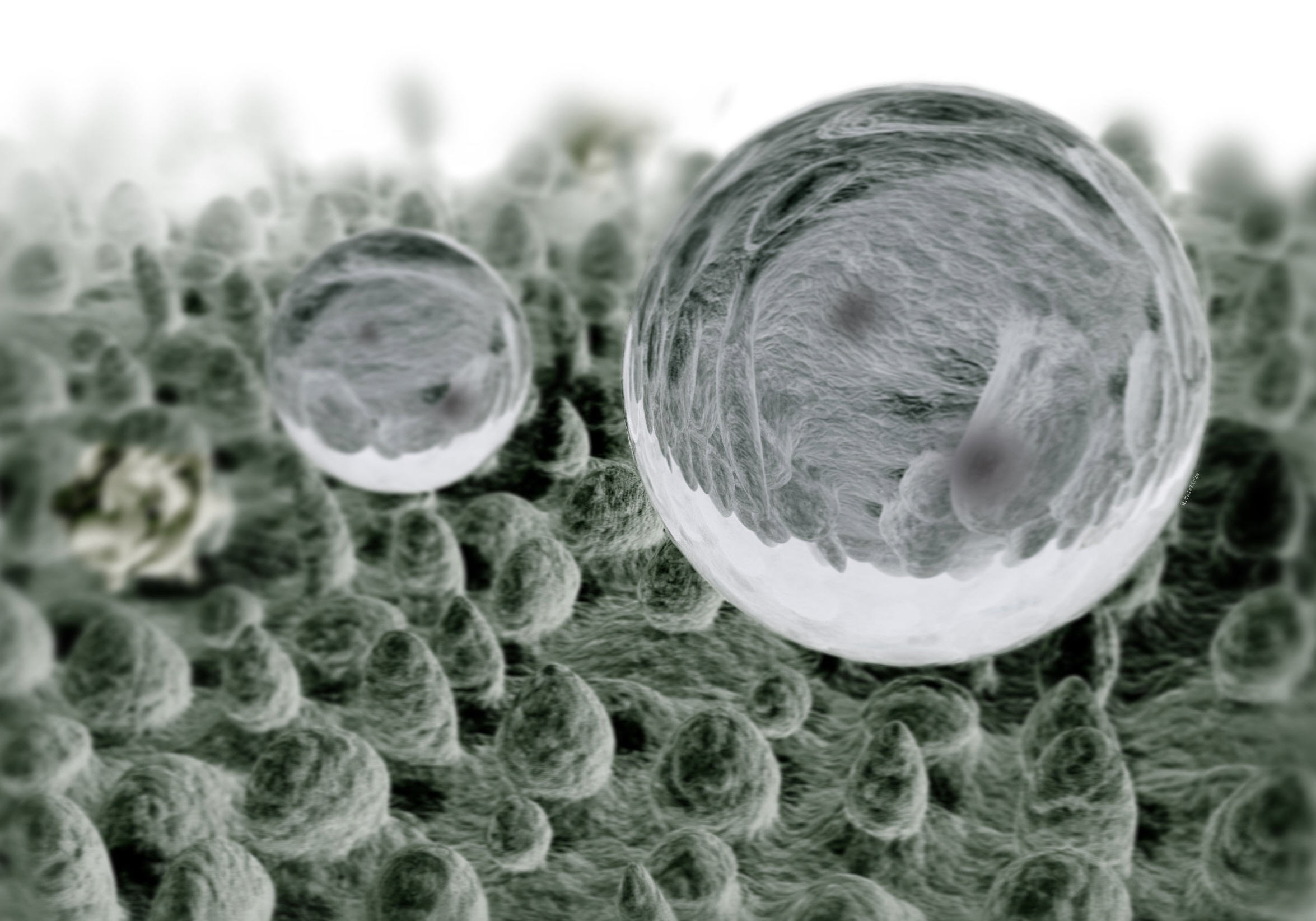

Recently, nanomaterials are widely preferred from textile manufacturers due to their excellent properties such as high mechanical strength, chemical resistance, water repellence, antibacterial properties etc. Still, a lot of research are carried in this area to improve textile products which already be used. To obtain nano-enhanced textiles, different kinds of processing techniques are needed because existing manufacturing processes are not very suitable. In this case, manufacturing costs, quality control and homogeneity of nanoparticle dispersion through the fabric become problematic issues. Another important issue to be considered for nanoparticle usage is any effects on human health and environment. Although some studies have focused on this issue, still toxicity of nanomaterials in textile product is not fully understood.

In fabric composites, conventional, natural or synthetic fibers are generally mixed with nanomaterials to enhance the performance or create novel properties to the fabric. Some examples of nanomaterials and benefits which can offer to textiles are listed below.

- Carbon black nanoparticles/nanofibers: electrical conductivity, high mechanical properties and abrasion resistance

- Carbon Nanotube: Excellent mechanical properties with lightweight, electrical conductivity and thermal conductivity

- Metal oxide nanoparticles: Antimicrobial properties, photocatalytic, electrically conductive and UV protection

- Metal nanoparticles: Antimicrobial, Aesthetic properties and solar cells

- Nanoclay: Fire retardancy, electrical and chemical resistivity, UV shielding

- Antibacterial and odor-reduced sports fabrics with improved mechanical properties

- Personal protective textiles with enhanced chemical, heat resistance and durable.

- For military purposes, flexible body armor, radio shielding and ballistic protection.

- Medical textiles with antimicrobial wound dressing and bedding

- Wearable electronics with conducting fabrics

https://nanografi.com/blog/nanotechnology-and-textiles/

Posted by Müberra Göktaş on November 30, 2016

Comments

Post a Comment