Batteries have become an important part in our electricity dependent modern lives. Every electronic device ranging from cell phones to computers rely on batteries for electricity storage. Even automobiles sector is shifting toward electric vehicles as the oil depletion and the environmental issues increase. The need for better battery with higher capacity, more stability and faster charging rates is in continuous demand. The solution is definitely in the development of new materials that have excellent properties which can increase the performance of the batteries. Graphene represent one of the best materials with extraordinary properties for the development of the batteries.

Image retrieved from: https://www.engadget.com

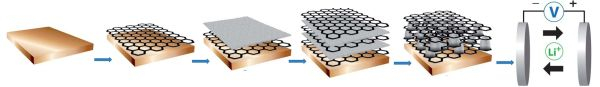

Graphene has very high surface area, hundred times better conductivity than copper and show good flexibility properties. Making battery out of graphene is one of the choices that battery developments have been working on. So far, hundreds of researches have been done that show the increase of the capacity, stability and charging rates of the graphene embedded batteries. Commercially, a Chinese company named Gongxu optoelectronics announced the first graphene battery with 4,800 mAh capacity and can be recharged in 13-15 minutes. Another company from Spain called Graphenano claims that they will produce graphene polymer cells that have 1,000 watt-hours per kilogram which is five times that of current lithium-ion cells. These developments show the importance of implanting nanomaterials such as graphene in different applications which can lead to excellent improvements in our daily lives.

Posted by Mohammed ZABARA on October 12, 2016

Comments

Post a Comment