Medical equipments used for health monitoring suffer from poor adhesion and adaption on the skin surface. Another problem of them is that, they become really bulky and heavy when they are connected to the digital devices and monitors which are used to record and show the data when needed. Researchers from University of Texas at Austin have focused on these problems and made the thinnest and most sensitive skin sensors ever made from wonder material graphene. The graphene sensors designed can precisely measure skin temperature, humidity as well as vital signs from brain, hearth and muscles.

Image Retrieved From: http://spectrum.ieee.org/nanoclast/semiconductors/...

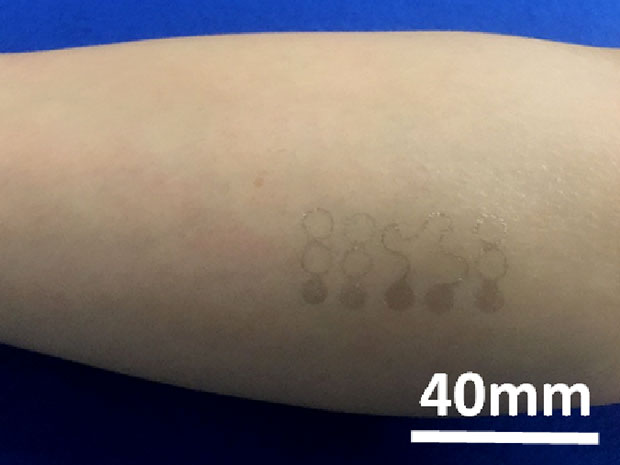

Dr. Akinwande says that electrical and mechanical properties of graphene are underestimated for a long time. He says when single-layer graphene is transferred to human skin, it is almost invisible. As graphene is a flexible material, it does not just stay on the skin as it is placed, it adjusts itself to the surface features of the skin. These adaption properties of graphene gave the material the best sensing properties measured in the first phase EKG, EEG and EMG signals sensing studies.

The advances in the research studies of Dr. Akinwande’s group will not be limited to the advances given above. The group is now planning to add some antenna features to the graphene sensors so that the health data collected by the graphene sensors can be transferred to the doctors and monitored anytime by computers or cell phones. This property can give graphene sensors a vital property, if the sensors are further designed with a logic that whenever a signal reaches or lowers down to a dangerous level for the patient sensors send emergency signals to the doctors or medical institutions.

If you want to use , buy here :

Posted by Huseyin ALAGOZ on April 21, 2017

Comments

Post a Comment