General Information about Silicon Carbide

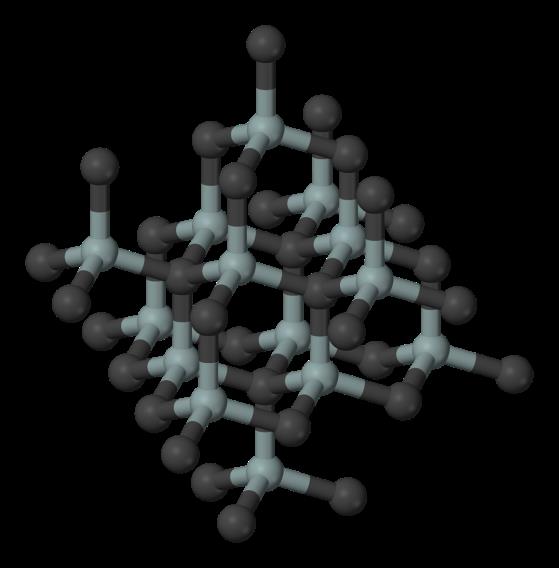

Silicon carbide (SiC), is a chemical compound containing silicon and carbon. It occurs in nature as the extremely rare mineral moissanite. Synthetic SiC powder has been mass-produced since 1893. This compound has a very high melting point which is 2730 oC.

Applications of Silicon Carbide Nanoparticles/Nanopowder

Silicon carbide nanoparticles/nanopowder are very hard materials and this property make them useful in ceramic applications such as ceramic bearing, textile ceramics, high frequency ceramics and ceramic engine parts. Silicon Carbide nanoparticles/nanopowder can be used for manufacturing of rubber tires. In order to obtain mirror coatings for high ultraviolet environments Silicon Carbide nanopowders/nanoparticle can be used. High-temperature spray nozzles such as those used in aeronautics, heating elements, sealing valves, and other mechanical products intended to resist extreme temperatures utilize Silicon Carbide nanoparticles/nanopowder in their construction. Silicon Carbide Nanoparticles/Nanopowder also can be used to produce various abrasive surfaces and substances, including polishing abrasives, the surfaces of grinding tools, actual grinding materials, and related products. Silicon carbide nanopowders/nanoparticle have also high thermal conductivity. Silicon Carbide nanopowders/nanoparticle can be used in high temperature sealing valves, high temperature spray nozzles, and high temperature fluid transport parts. In order to increase strength and heat resistance of composite materials Silicon Carbide Nanoparticles/ Nanopowder can be used.

Technical Properties of Our Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5% 20 nm Laser Synthesized Product

| Purity (%) | 99.5 |

| Color | grayish white |

| Average Particle Size (nm) | 20 |

| Bulk Density (g/cm3) | 0.03 |

| True Density (g/cm3) | 3,32 |

| Specific Surface Area (m2/g) | 80.0-130.0 |

| Morphology | cubic |

| Manifacturing Method | laser synthesized |

You may order Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5% 20 nm Laser Synthesized from the link below:

Technical Properties of Our Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5+%, 50-70 nm Product

| Purity (%) | 99.5+ |

| Color | grayish white |

| Average Particle Size (nm) | 50-70 |

| Bulk Density (g/cm3) | 0.05 |

| True Density (g/cm3) | 3,32 |

| Specific Surface Area (m2/g) | 40.0-85.0 |

| Zeta Potential (mV) | -27,5 |

| Morphology | cubic |

| Manifacturing Method | CVD |

You may order Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5+%, 50-70 nm from the link below:

Technical Properties of Our Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5+%, <70 nm Product

| Purity (%) | 99.5+ |

| Color | grayish white |

| Average Particle Size (nm) | <70 |

| Bulk Density (g/cm3) | 0.05 |

| True Density (g/cm3) | 3,32 |

| Specific Surface Area (m2/g) | 20.0-55.0 |

| Zeta Potential (mV) | -27,5 |

| Morphology | cubic |

| Manifacturing Method | CVD |

You may order Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5+%, <70 nm from the link below:

Technical Properties of Our Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5+% , 790 nm Product

| Purity (%) | 99.5+ |

| Crystal Type | beta |

| Average Particle Size (nm) | 790 |

| Density (g/cm3) | 3,22 |

| Decomposition Temperature (K) | 2973.0 |

| Hardness (Mohs) | 9,5 |

| Thermal Expansion Coefficient (373k) | 6.7 × 10-6 |

| Thermal Expansion Coefficient (1173k) | 3.0 × 10-6 |

| Heating Power (KJ/mol) | 30.34 |

| Compressibility Coefficient | 0.2 × 10-6 |

You may order Silicon Carbide (SiC) Beta Nanoparticles/Nanopowder, 99.5+% , 790 nm from the link below:

Technical Properties of Our Silicon Carbide (SiC) Beta 99.5+%,<2,6 um whisker Product

| Purity (%) | 99.5 |

| Crystal Type | beta |

| Daimeter (um) | .2,6 |

| Length/Diameter | ≥20 |

| Density (g/cm3) | 3,22 |

| Decomposition Temperature (K) | 2973.0 |

| Hardness (Mohs) | 9,5 |

| Thermal Expansion Coefficient (373k) | 6.7 × 10-6 |

| Thermal Expansion Coefficient (1173k) | 3.0 × 10-6 |

| Heating Power (KJ/mol) | 30.34 |

| Compressibility Coefficient | 0.2 × 10-6 |

You may order Silicon Carbide (SiC) Beta 99.5+%,<2,6 um from the link below:

Technical Properties of Our Silicon Carbide (SiC) Beta 99.5+%, D50 1.5-35 um Product

| Purity (%) | 99.5+ |

| Crystal Type | beta |

| Average Particle Size (um) | 01.05.1935 |

| Density (g/cm3) | 3,22 |

| Decomposition Temperature (K) | 2973.0 |

| Hardness (Mohs) | 9,5 |

| Thermal Expansion Coefficient (373k) | 6.7 × 10-6 |

| Thermal Expansion Coefficient (1173k) | 3.0 × 10-6 |

| Heating Power (KJ/mol) | 30.34 |

| Compressibility Coefficient | 0.2 × 10-6 |

You may order Silicon Carbide (SiC) Beta 99.5+%, D50 1.5-35 um from the link below:

Comments

Post a Comment