Antimony Tin Oxide (ATO) Nanoparticles/Nanopowder and Applications of Antimony Tin Oxide Nanopowders/Nanoparticle

Antimony Tin Oxide (ATO) Nanoparticles/Nanopowder and Applications of Antimony Tin Oxide Nanopowders/Nanoparticle

Description of Antimony Tin Oxide (ATO)

Antimony Tin Oxide is a chemical compound consists of three different element, Antimony, Tin and Oxygen with the general formula of Sb2SnO5.

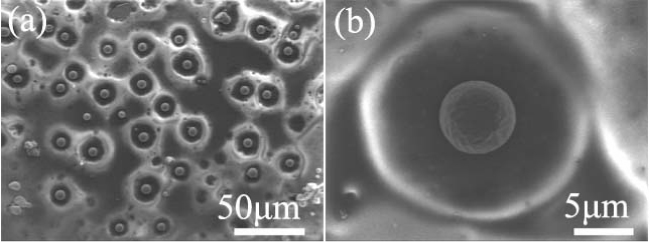

Hallow ATO Spheres*

Applications of Antimony Tin Oxide (ATO) Nanoparticles/Nanopowder

In the construction of LEDs, LCDs and other lights and display devices, ATO nanoparticles/nanopowder are used. For energy storage Antimony Tin Oxide nanoparticles/nanopowder are very useful. Antimony Tin Oxide nanoparticles/nanopowder serve as UV protector when they are applied as transparent UV protection tool. Antimony Tin Oxide nanoparticles/nanopowder show resistance to many different organic and inorganic chemicals and this property makes Antimony Tin Oxide nanoparticles/nanopowder an ideal additive for general corrosion-resistance. Antimony Tin Oxide Nanopowders/Nanoparticle can be widely used in the industry of coating, chemical fiber and polymeric membrane as anti-static material. When Antimony Tin Oxide Nanopowders/Nanoparticle are compared with other conductive materials like graphite and metallic powders, Antimony Tin Oxide nanoparticles/nanopowder have more advantaged properties in dispersion, weather-ability and wear resistance.

Technical Properties of Our ATO Nanoparticles/Nanopowder, 28nm, 99.995+% Product

| Purity % | 99.995+ |

| Bulk Density (g/cm3): | ≤0.95 |

| Color | light blue |

| AVERAGE PARTICLE SIZE (nm): | 28 |

| Electrical Conductivity (Ω) | 108 |

| Resistivity (Ω.cm) | 50 |

| Heat Resistance(oC): | 1100 |

| SPECIFIC SURFACE AREA (m2/g): | >95 |

| Loss in Drying (%) | 0.5 |

| PH | 4.0~7.0 |

You may order ATO Nanoparticles/Nanopowder, 28nm, 99.995+% from the link given below:

Comments

Post a Comment