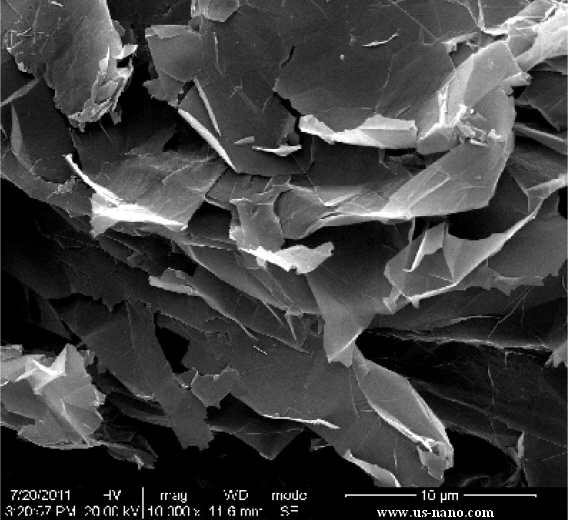

Graphene nanoplatelets (GNPs) represent a new class of carbon nanoparticles/nanopowder with multifunctional properties. Graphene nanoplatelets are unique nanoparticles/nanopowder consisting of small stacks of graphene sheets having a platelet shape that are identical to those found in the walls of carbon nanotubes, but in a planar form. Graphene nanoplatelets can replace carbon fiber, carbon nanotubes, nano-clays, or other compounds in many composite applications. Graphene nanoplatelets unique size and platelet morphology makes these particles especially effective at providing barrier properties, while their pure graphitic composition makes them excellent electrical and thermal conductors. Graphene nanoplatelets can improve mechanical properties such as stiffness, strength, and surface hardness of the matrix material.

When graphene nanoplatelets are added at 2-5wt% to plastics or resins they make these materials electrically or thermally conductive and less permeable to gasses. Graphene nanoplatelets have naturally occurring functional groups like ethers, carboxyls, or hydroxyls that can react with atmospheric humidity to form acids or other compounds. These functional groups are present on the edges of the particles and their wt% varies with particle size. Hydrogen or covalent bonding capability can be added through functionalization at sites on the edges of the platelets. The unique manufacturing processes are non-oxidizing, so material has a pristine graphitic surface of sp2 carbon molecules.

The multifunctional property improvements offered by graphene nanoplatelets make them ideal additives for applications where several property improvements are required. Significant processing or material cost savings can be achieved by reducing or eliminating the need for multiple films or expensive lamination processes.

- Achieve effective electrical conductivity with improved stiffness and toughness in cost-sensitive applications

- Improve the cross-fiber electrical conductivity and ESD and thermal conductivity of carbon-fiber composites

- Produce lower cost nanotube-containing conductive polymers with improved barrier properties

- Render fiberglass electrically conductive without requiring any changes in processing or fabrication procedures

- Improve barrier properties while also enhancing stiffness, strength, and scratch-resistance without reducing toughness

- Impart inherent electrical conductivity for dissipation of static electricity and excellent barrier protection for use in applications involving flammable gases or liquids.

Applications of Graphene Nanoplatelets:

Graphene Nanoplatelets are used in ultra-capacitor electrodes.

Graphene Nanoplatelets are used in anode materials for lithium-ion batteries.

Graphene Nanoplatelets are used in conductive additive for battery electrodes.

Graphene Nanoplatelets are used in electrically conductive inks.

Graphene Nanoplatelets are used in thermally conductive films and coatings.

Graphene Nanoplatelets are used as an additive for lightweight composites.

Graphene Nanoplatelets are used in films or coatings for EMI shielding.

Graphene Nanoplatelets are used in substrate for chemical and biochemical sensors.

Graphene Nanoplatelets are used in barrier material for packaging.

Graphene Nanoplatelets are used as an additive for super-strong concrete and metal-matrix composites.

Comments

Post a Comment