The main insulating material used in micro-technology is Silicon Dioxide, which in chemical symbols is written as SiO2. In semiconductor technology, SiO2 thin film layers are mainly used as dielectric material film in transistors, capacitors (DRAM) or flash-memories.

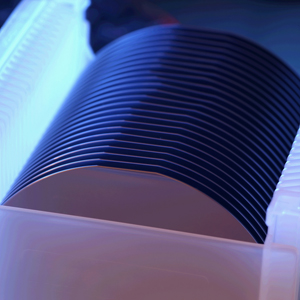

Silicon Oxide Wafers are produced using crystallization, solid state and other ultra-high purification processes such as sublimation. This process forms a cylindrical ingot, which is then sliced and polished to form wafers.

Thermal oxide is a kind of "grown" oxide layer, compared to CVD deposited oxide layer, it has a higher uniformity, and higher dielectric strength, it is an excellent dielectric layer as an insulator . In most silicon- based devices, thermal oxide layer play an important role to pacify the silicon surface to act as doping barriers and as surface dielectrics.

The simplest way to produce an insulating silicon oxide layers (SiO2) on silicon wafers is to oxidize silicon with oxygen, which can be carried out via high dry or wet oxidation processes. In both cases, silicon reacts with oxygen leading to a moving interface towards the substrate. Thermal oxide is normally grown in a horizontal tube furnace

Dry oxidation typically takes place at temperatures in between 850 and 1200°C and it demonstrates low growth rates. It does allow very good thickness uniformity and purity. Therefore, this is the preferred way to produce high quality thin silicon oxide layers. Thicker oxide layers are typically produced by wet oxidation where the growth rate is significantly increased.

Applications of Silicon Oxide (SiO2) wafers:

- Silicon Oxide (SiO2) wafers are used as dielectric material.

- Silicon Oxide (SiO2) wafers are used in Micro Electro Mechanical Systems (MEMS) devices.

- Silicon Oxide (SiO2) wafers are used as an antireflection layer on e.g. solar cells.

- Silicon Oxide (SiO2) wafers are used as a hard mask for diffusion.

- Silicon Oxide (SiO2) wafers are used for wet or dry chemical etching

- Silicon Oxide (SiO2) wafers are used as an isolator between integrated devices.

Comments

Post a Comment