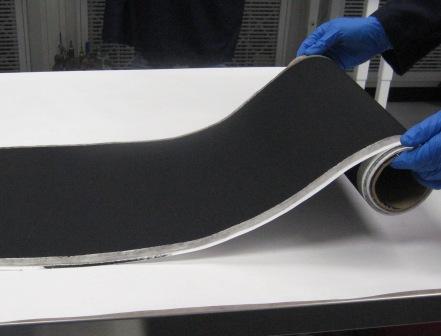

Buckypaper is a macroscopic aggregate of carbon nanotubes (CNT) which is ultrathin, electrically conducting and 10 times lighter than steel while still being 250 times stronger. The tough material can be folded, cut with scissors, like notebook paper. Composed of tube-shaped carbon molecules 50,000 times thinner than a human hair, Buckypaper possesses unique properties enabling it to conduct electricity like brass or steel and disperse heat like metal or silicon.

In the 1980s a carbon atom arrangement called Carbon 60, or Buckminsterfullerene, was discovered that turned out to be twice as hard as diamond. The pattern of carbon atom links was found to be identical with the basic polyhedron that R. The flat-sheet hexagonal form of carbon could wrap around itself to create long hollow tubes. These nanotubes have a tensile strength 40 times greater than that of the carbon fibers currently used in aircraft. In 1985, a team of scientists at Rice University, while conducting an experiment examining how stars produce carbon serendipitously discovered a ball of 60 carbon atoms, which scientists named "Buckyballs." The naming came from the buckminsterfullerene, the 60 carbon fullerene. Buckypaper is the brainchild of professor Ben Wang, an industrial engineer at Florida State University who discovered the carbon nanotubes of Buckyballs would stick together and could be produced into a small film.

Buckypaper is created from carbon nanotubes, which can be magnetically aligned during fabrication. Carbon nanotubes are suspended in water. Then the suspension is filtered the onto a membrane support. After drying, the paper is removed from the support, leaving a free-standing paper.

Buckypaper can be implicated in military vehicles to make them lighter and stronger, to make transporting these vehicles to trouble areas faster and more efficient. Also, buckypaper in the future is predicted to be applicable as a large-scale electron-field emitter for flat-panel displays, as a thermal conductor for superefficient heat sinks and as high-current protective film for the exteriors of airplanes. Such film would allow lightning strikes to flow around a plane and dissipate without damaging it.

Buckypaper Applications:

Buckypaper is used in airplane industry.

Buckypaper is used in military armor plating.

Buckypaper is used in biological tissues.

Buckypaper is used in LCD (computer and TV) screens.

Buckypaper is used in sensor technology.

Comments

Post a Comment