In electronics, solders are main material to connect electrical components to substrates which are generally printed circuit boards. Although they are cheap, they are not effective if long term performance is considered since solders have low resistivity to corrosion relatively. Since corrosion reduce reliability, the cost of advanced technological systems such as RADAR, SONAR, LIDAR and more increase. In addition, small signals can be lost, and in huge data transfer, some of the data can be lost also especially which may lead catastrophic failures in critical systems. For instance, surface to air missiles can be launched to target which is not exist if the data coming from detection systems is noisy. Therefore, corrosion protection is necessary, and silver conductive adhesive paste is an essential candidate to replace PbSn solders due to its resistivity to corrosion. Silver conductive adhesive paste provide not only noisy reduction but also electromagnetic interference which is essential at electronic warfare. It also can be used as electrostatic discharge protection, as a safety regulation.

In some applications silver conductive adhesive paste is mixed and used with another materials. That may reduce the conductivity but it increase the resistivity for corrosion and adapt the material for usage of specific applications such as thick film coating to make the film anti-reflective and protect against corrosion.

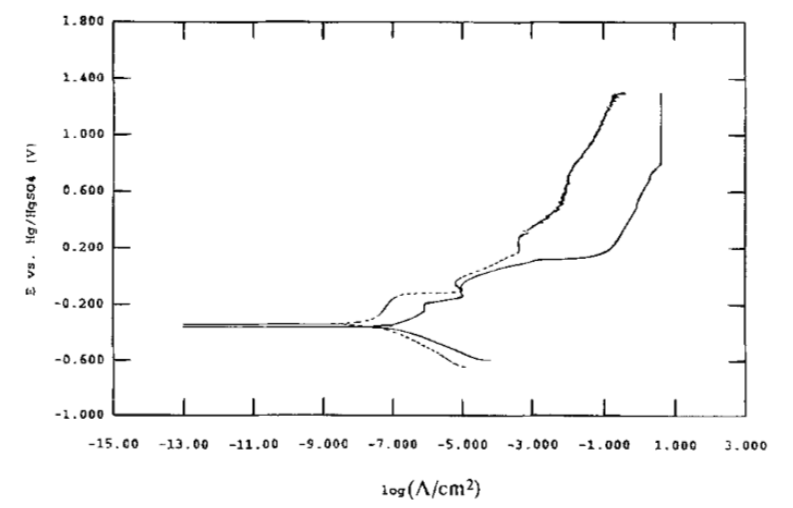

Figure 1: Potentiodynamic polarization curves for an Ag foil (solid line) and Ag paste (dashed line) samples measured in a droplet of water.

V.Brusic, G.S. Frankel, J.Roldan, R,Saraf, Corrosion and Protection of a Conductive Silver Paste, 1995

As an example experiment, metal coverage in silver adhesive conductive paste is compared to coverage in silver foil. They concluded that the corrosion rate of silver foils which is measured in terms of current density per geometric area is an order of magnitude higher than that of silver paste as you can see in Figure 1. Therefore, polymeric coverage for silver conductive adhesive paste is approximately %90. They also conducted an experiment that, the anodic dissolution of silver particles is reduced in an aqueous solution containing benzotriazole, and behavior of the silver paste become complementary to that of gold paste. In addition, oxygen evaluation reaction is extremely suppressed.

Not only for electrical conductivity, but also for corrosion protection, silver conductive adhesive paste being used. Its advantage make it essential for applications required reliability, and it can be functionalized to serve any purpose, and in the future more research will be conducted, and more applications will be found out.

So nice inforamtions about strain gauge adhesive electrical parameters

ReplyDelete