Conductive adhesive paste is the glue form of conductive adhesive, and more advantageous than soldering processes. Since it is more flexible than solder, it is able to cope with vibrations better, and its curing temperature is below the soldering temperature which is important when soldering temperature can be harmful for substrates, so conductive adhesive paste is excellent way for electrical connections on temperature-sensitive substrates, and components. Silver conductive adhesive paste is the most conductive one in conductive adhesives, and circuit resistivity 8.0x10-6Ω cm for highly conductive paste. Therefore, it is commonly used in applications in which low electrical resistance needed.

Figure 1: Silver Conductive Adhesive Paste

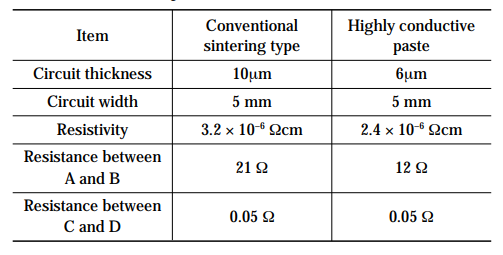

Although it is expensive for use in solar panels, low resistivity prevent loss of power, so it increase the effectivity. In terms of strength, silver conductive adhesive paste increase the lifetime of solar cells, so that makes it crucial for reliability of solar panels since manufacturers want to provide 25-year warranties. As an applications, in order to reduce the power loss to minimum in dye-sensitized solar cell caused by increase of battery resistance while it is charging, silver conductive adhesive paste have been used for current collection wiring of transparent conductive glass substrate. To support this application, a group tested the silver adhesive conductive paste with conventional sintering type in the table below.

A. ONO, K. OKADA, N. KONDO, M. KURUSAWA, M. Kurosawa, M. Ohyama, S. Kodate, K. Okamoto, M. Ito, Applications of Hıghly Conductive Silver Paste, 2008

Low resistivity, and mechanical properties of silver conductive adhesive paste allow it to construct many different connection construction. In addition, they can be used for surface mount to replace solder pastes, since they are low in weight and requires less volume than thin solders. For example, in a case study, to construct Z-axis interconnecting for a flip-chip plastic ball grid array package with a 150 µm die pad pitch, they used a silver filled conductive adhesive, they concluded that it maintained strength after 1000 cycle of thermal cycling from -55° C to 120°C.

Despite the fact that silver conductive adhesive paste is expensive to make ordinary connections, low resistivity, flexibility, low curing temperature, form an exclusive access to efficiency and effectivity. As a result, it is necessary for research which electrical qualities considered.

Comments

Post a Comment