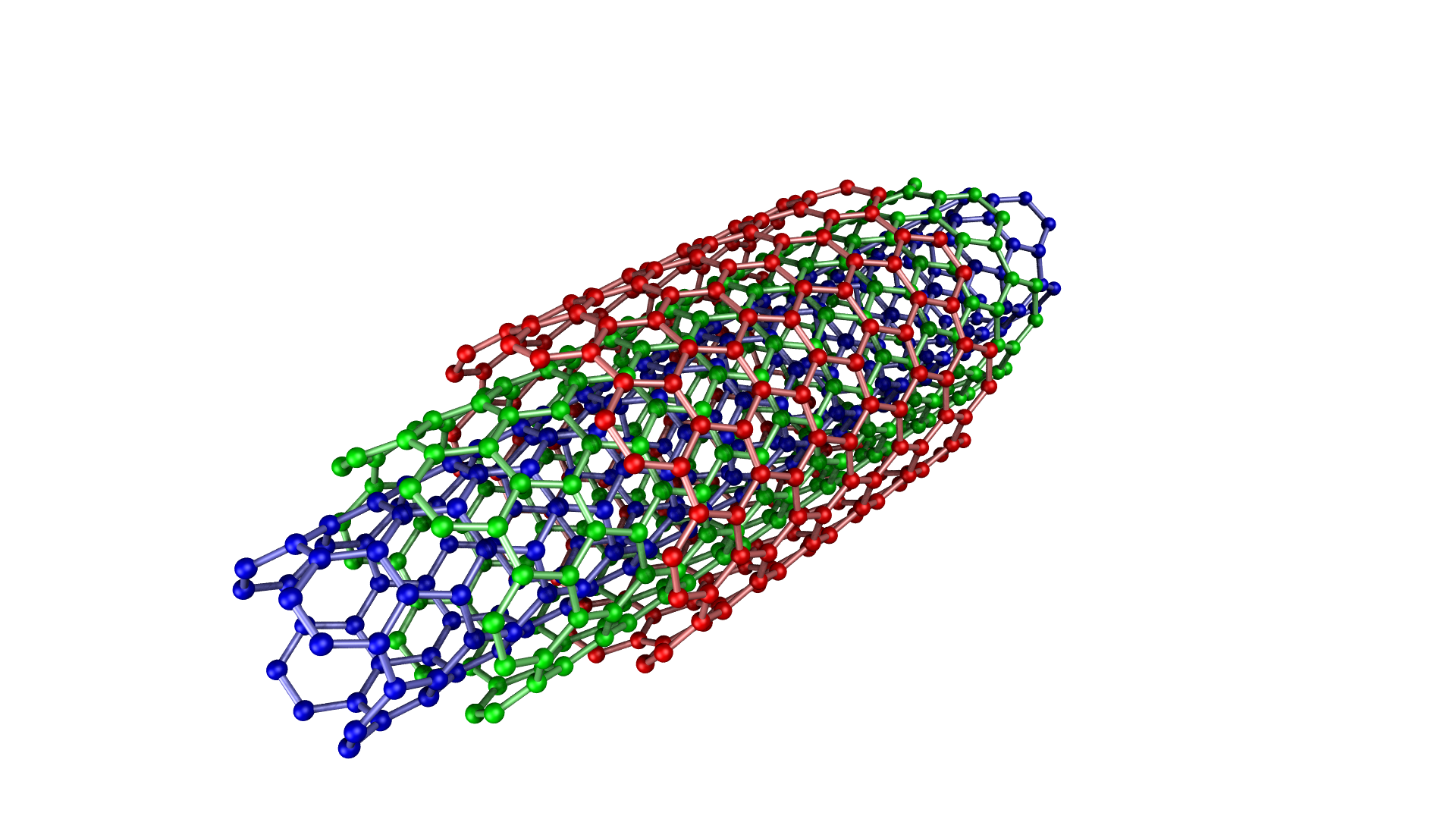

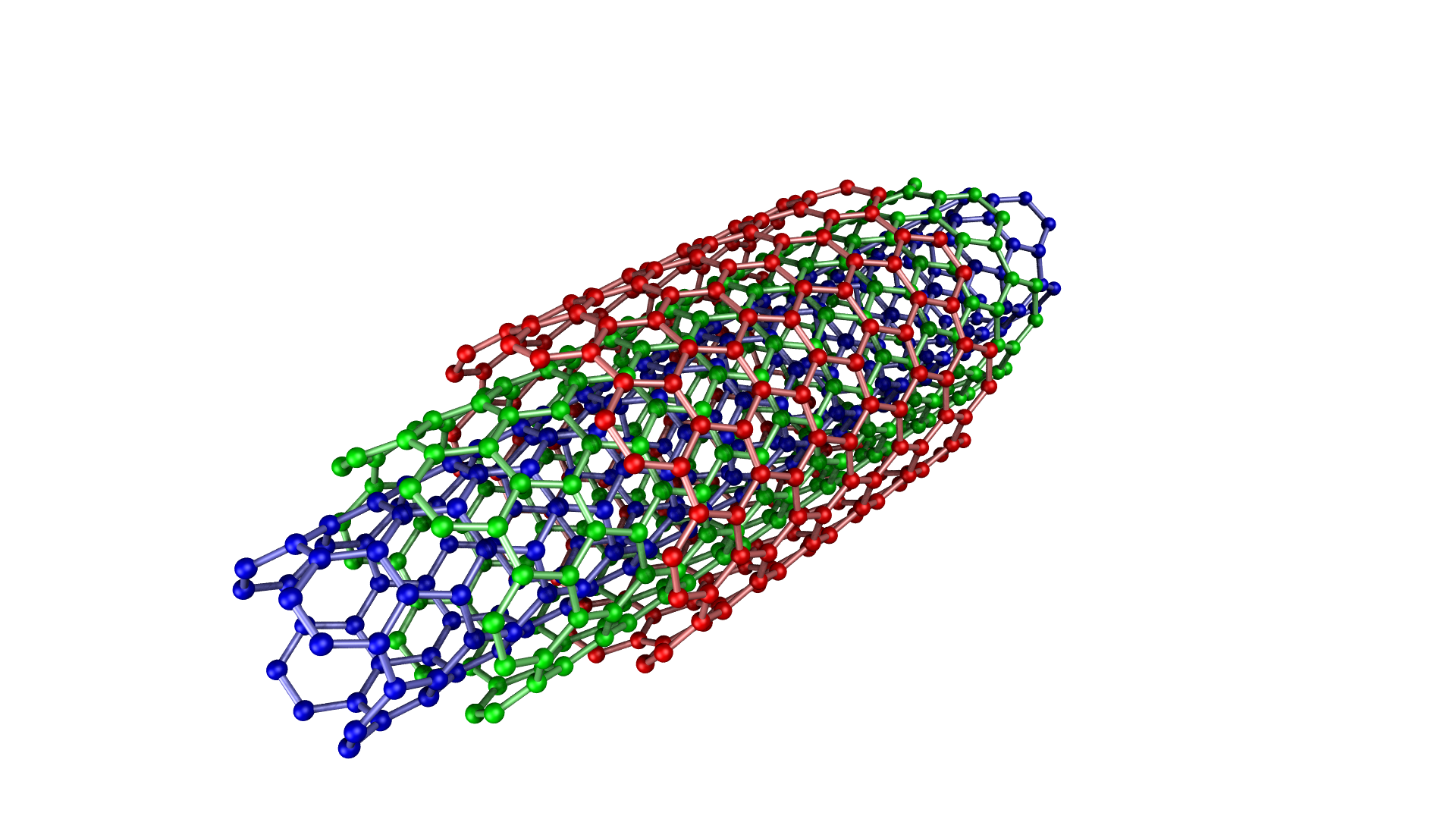

Multi Walled Carbon Nanotubes

Multi walled carbon nanotubes have a lot in common in specific regards, yet they additionally have striking contrasts. SWNTs are an allotrope of sp2 hybridized carbon. The diameter of Multi-walled carbon nanotubes might be 30 nm when compared to 0.7– 2.0 nm for ordinary SWNTs. The primary properties of carbon nanotubes bear an extensive variety of novel applications and changes inMulti-walled carbon nanotubes (MWNTs) and Single-walled carbon nanotubes (SWNTs) the performance of existing ones. For example:

Multi-walled carbon nanotubes are ised in Electrical area: Multi-walled carbon nanotubes are very conductive when appropriately coordinated into a composite structure. One must know that the outer wall alone is conducting, whereas the inner walls are not.

Multi-walled carbon nanotubes are used in Morphology area: Multi-walled carbon nanotubes have a high aspect ratio with lengths regularly more than 100 times the diameter, and in specific cases significantly higher.

Multi-walled carbon nanotubes are used in Physical area: Defect– free, individual, Multi-walled carbon nanotubes have an astounding elasticity and when incorporated into a composite, for example, a thermoplastic or thermoset mixes, can altogether expand its quality.

Multi-walled carbon nanotubes are used in Thermal area: Multi-walled carbon nanotubes have a thermal stability more than 600 °C.

Multi-walled carbon nanotubes are used in Chemical area: Multi-walled carbon nanotubes are an allotrope of sp2 hybridized carbon like graphite and fullerenes , hence possess great chemical stability. Be that as it may, one can functionalize the nanotubes to make composites strong and dispersible.

For Related Products, please visit:

Comments

Post a Comment