- Heavy water is mainly used in nuclear power plants as the cooling agent and huge amounts of heavy water is produced in order to meet the regular needs of the nuclear plants. The problem with heavy water is that its production is very costly and million tonnes of carbondioxide gas is released during production of heavy water every year.

- Researchers from University of Manchester led by Marcelo Lozada-Hidalgo showed that heavy water production is also possible with the use of wonder material graphene. Their research revealed that membrane structures made by graphene could be used for this purpose. Furthermore, use of graphene membranes for heavy water production is very practical as well as feasible for industrial scale production. Graphene can directly eliminate building massive high power production plants for production purpose and provide fairly big amounts of cost reduction.

Image Retrieved From: http://www.nanowerk.com/nanotechnology-news/newsid=47036.php

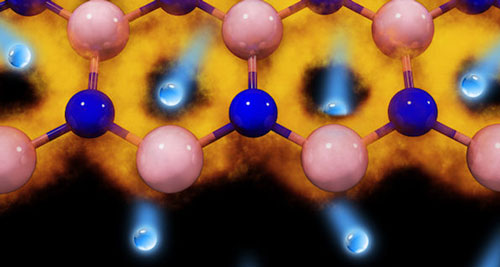

- Graphene membrane is shown to be an effective filter for heavy water production because it efficiently separate different isotopes of hydrogen which is essential during production process. In order to produce the graphene membrane, researchers used chemical vapor deposition process. They additionally deposited palladium nanoparticles on the membranes as a catalyst. This process can be designed to become a cost and energy efficient process by small changes.

- In addition to the information above, collecting heavy isotopes from water has also an environmental aspect. Release of these heavy substances to nature is a dangerous treat and this makes graphene membrane is an environment-friendly alternative thereby collecting these isotopes.

Comments

Post a Comment