Reduced graphene oxide is produced from graphene oxide by ultrasound, chemical or thermal reduction. During the reduction step, most of the oxygen functional groups are removed from graphene oxide, so that the resulting reduced graphene oxide has very similar properties to pure graphene. However, reduced Graphene Oxide is not defect-free impure than pure graphene.

The main difference between graphene oxide and reduced graphene oxide is the decrease in the ratio of the number of oxygen atoms to that of carbon atoms present in the structure. This article discusses reduced Graphene Oxide, its properties, production methods, and applications.

9 Core Properties of rGO

The core properties of reduced Graphene Oxide are given below:

- The electrical conductivity of Reduced Graphene Oxide is 666,7 S/m.

- rGO is mainly produced by the chemical reduction method.

- Reduced Graphene Oxide is black in color.

- rGO exists in the powder form.

- rGO is odorless.

- BET surface area of reduced Graphene Oxide is 422.69 – 499.85m2/g.

- The density of Reduced Graphene Oxide is 1.91g/cm3.

- rGO is insoluble in nature.

- The humidity found in Reduced Graphene Oxide is in the range of 3.7 - 4.2%.

Elementary Analysis of Reduced Graphene Oxide

Reduced Graphene Oxide is composed of four elements, as shown below:

- The oxygen content in reduced Graphene Oxide varies from 13 – 22%.

- The hydrogen content in reduced Graphene Oxide ranges from 0 – 1%.

- The nitrogen content in reduced Graphene Oxide Nitrogen ranges from 0 – 1%.

- The carbon content in reduced Graphene Oxide Carbon varies from 77 – 87%.

Five main methods of graphene oxide reduction in 2019

The main reduction methods for graphene oxide are the following:

1.Thermal reduction

- Reduction by heating

- Microwave and photoreduction

2.Chemical reduction

- Reduction with chemical agents

- Reduction by photocatalysis

- Reduction by multiple steps

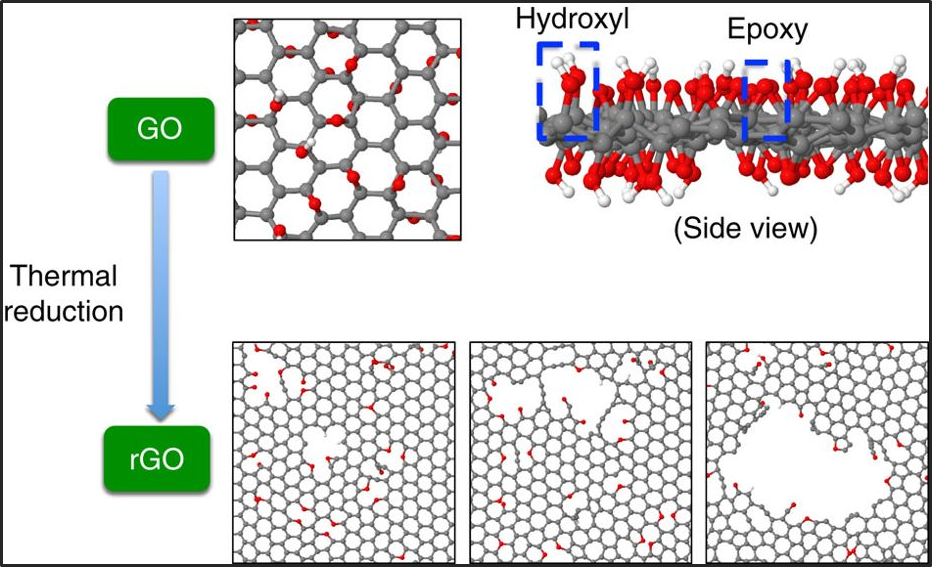

1.Thermal reduction of Graphene Oxide

GO can be reduced by heat treatment and the process is called thermal reduction. The mechanism of exfoliation happens due to the expansion of CO or CO2 gases present within the spaces between the graphene sheets during rapid heating of the graphene oxide. The abrupt change of temperature causes the functional groups inserted in the carbon plane to decompose in gases, creating a great pressure inside the sheets. Based on a suitable equation of state, at a temperature of 300 °C, a pressure of 40 MPa can be generated, while at 1000 °C it can reach 130 MPa. Unfortunately, in the literature it was not found which equation of state could be appropriate to model this phenomenon, however, it is important to emphasize that it has been reported that pressure of only 2.5 MPa is sufficient to separate two sheets of GO.

"Via a thermal annealing process (that is, thermal reduction), some of atoms are removed, resulting in nanopores formed in rGO materials with a variety of sizes. All structures are represented as ball and stick with carbon, oxygen and hydrogen atoms in grey, red and white colour, respectively."

Image obtained from https://www.nature.com/articles/ncomms9335

2.Chemical reduction of Graphene Oxide

The reduction by chemical agents is based on the chemical reactions with GO. Usually, the reduction can be carried out at ambient temperature conditions or by using moderate heating. As a result, this method has certain advantages over thermal reduction because no special equipment is required. One of the main chemical agents used for the reduction of graphite oxide is hydrazine, which was used even before the discovery of graphene. Recently, boron sodium hydride has been shown to be more effective as a reducing agent for GO, achieving improvements in conductivity when compared to hydrazine.

Applications of Reduced Graphene Oxide

Reduced Graphene Oxide is mainly used in the below sectors:

- Graphene research

- Biomedical

- Printable graphene electronics

- Batteries

- Supercapacitors

Six particular applications of Reduced Graphene Oxide have been discussed below:

- Reduced Graphene Oxide is vital for use in the electronics sectors. It has applications in solar devices and light emitting diodes. These products necessarily require visible light transparent electrodes and reduced Graphene Oxide fulfills this requirement.

- We also find its use in lithium-ion batteries for energy storage. This works by adsorbing electrically insulating metal oxide nanoparticles on Reduced Graphene Oxide to boost the performance of batteries.

- The use of reduced Graphene Oxide has been found to be valuable in biosensors. This has been used as a component in biological sensors to detect biomolecules.

- One of the innovative uses of Reduced Graphene Oxide has been found in drug delivery systems, specifically in anti-cancer drugs.

- Reduced Graphene Oxide has the capacity to quench fluorescence in biosensors that use FRET (Fluorescence Resonance Energy Transfer) effect.

- A group of researchers in China have stitched reduced graphene oxide nanosheets with highly conductive, ultra strong and tough graphene films using a small quantity of crosslinker. They highlighted that by bridging the π-π bonding agent among reduced graphene oxide nanosheets can significantly improve its properties, such as toughness, tensile strength, resistance to mechanical damage, EMI shielding capability, and electrical conductivity. The new product formed does not only exhibit the tensile strength of 1.1 GPA but also shows the capability to absorb the mechanical energy and transport charge. What inspired the researchers to do this was the sophisticated interface architecture, layered structure, and development at an ambient temperature of Nacre. Nacre is an element having a robust structure, regardless of the brittle nature of the ceramic particles. According to the researchers, long-chain π-bridging has the capability to improve toughness, tensile strength, and electrical conductivity. Approximately, less than 7% weight of π-π bonding agent showed remarkable results. This is also useful in the alignment of graphene nanosheets.

Conclusions

In this article, we briefly described the properties, production methods and different ways in which reduced graphene oxide is being used. Due to the excellent properties of Reduced Graphene Oxide, both thermal and electrical, it has the possibility of being functionalized to provide other specific properties. Reduced Graphene Oxide is a very promising material, very useful for diverse applications in many areas of science, from advanced materials, biomedical applications, engineering, electrochemistry, among many others. The new researches on Reduced Graphene Oxide can discover a lot of new applications.

Read more about Reduced Graphene Oxide on nanografi.com:

Comments

Post a Comment